Multifeeder MFT 350 ip3 Friction Feeder with Accutip Software

Multifeeder MFT 350 ip3 Friction Feeder with Accutip Software

Description

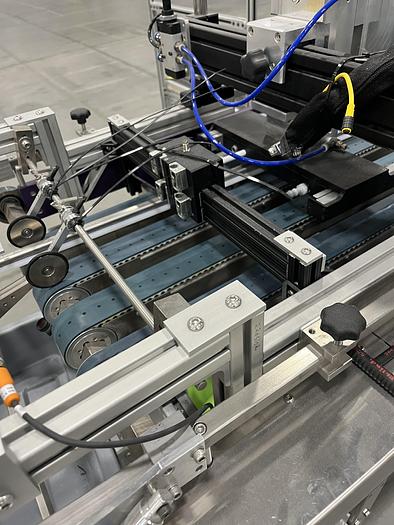

This incredible set-up starts by feeding flat, unfolded, carriers from a stack in the infeed hopper of the feeder. As the product travels from the base feeder to the VTC, a set of scoring rollers will score the product in the run direction. The carrier will then be placed onto a servo driven VTC 4000-550 vacuum track conveyor. The VTC will provide a vacuum generator which will hold the products in place on the conveyor with vacuum to expose the top surface of the product. The transport belts on the VTC are a timing belt to ensure the belts track the same speed for future print operations such as ink jetting.

The carrier product will then pass beneath the first MFT IP 350XED Industrial Performance Friction Feeder where the first insert will be applied. A second MFT IP 350XED Industrial

Performance Friction Feeder will apply the second insert. The first and second inserts can each have a barcode which will be scanned to ensure they match. If they don't match the product will be tracked, to the end of the conveyor, where it will be rejected into a bin. The reject will provide a reject confirmation sensor to ensure the product was rejected from the system. A barcode reader will be added to the VTC to scan base products with a 2D code. When present the 2D code on the base product will be used to be matched to the two other readers.

We have various inkjet printers available that can be installed on this line or you can utilize your preferred manufacturer. We have NEW Hawk UV LED, MCS, VideoJet, and KirkRudy.

The system can be operated in two different modes. Mode one would allow the data from one of the 3 barcodes that are read to be sent to the print system so that the identical barcode and human readable can be printed on the carrier after it has been folded. Mode two will use the Data File Lookup and Print Command Software. This will allow the data from one of the 3 barcodes to be looked up in a data file (Preferred file type is a MRDF file) and the associated 2D barcode and human readable for that record would then be printed onto the top surface of the final folded base product.

Prior to exiting the conveyor the carrier will be glued and folded in half. Good products will be allowed to pass the reject assembly to be collected on the shingling conveyor for an operator to process.

The line consists of the following components: (3) Multifeeder MFT 350ip3 with Accutip Software

Vacuum Track Conveyor

Scoring Device

Keyence 2D Readers

Nordson Glue System

Pressure Rollers

Folding Assembly

APL Bulk Product Loader

Reject Error System & Collection Bin

PLC with HMI Product Inspection & Tracking System

Data File Look-up & Print Command Software

At Capital Equipment Solutions, we pride ourselves on being your go-to partner for new and pre-owned printing and packaging equipment, as well as turnkey solutions, including delivery and installation. Our extensive inventory features high-quality, late-model equipment from industry-leading manufacturers such as Muller Martini, Bobst, Brausse, Heidelberg, Komori, KBA, MANRoland Goss, and more. In addition to our turnkey services, our expert operations team can assist with insurance restoration, removals, relocation, and plant liquidation. We’re dedicated to providing you with personalized guidance and comprehensive solutions that cater to your unique production requirements. Don’t forget to explore our full range of offerings on our website, and feel free to reach out to our expert team for any questions or assistance.

Specifications

| Manufacturer | Multifeeder |

| Model | Inserting & Addressing Line - MFT 350ip3 |

| Condition | Used |